Clean workshops are generally closed, with few doors and windows. In the event of a fire, the heat of the flue gas is not easy to radiate outward, resulting in the retention of flue gas, a sharp increase in heat, and more likely to cause injuries and deaths due to high temperature and hypoxia. Therefore, it is important to take fire safety measures.

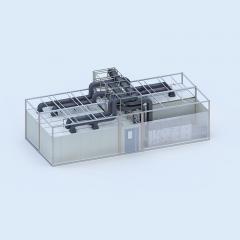

Clean workshop

Note 1: In the decoration of clean workshops, we must pay attention to the combustion performance of the decoration materials and minimize the use of some polymer synthetic materials to avoid the generation of a large amount of smoke during the fire, which is not conducive to escape.

Note 2: Strict requirements are imposed on the electrical pipelines, and steel pipes should be used wherever possible to ensure that electrical circuits do not become a way for fire to spread.

Note 3: Keep the environment clean in the clean workshop. Keep all materials neat and away from heat sources. Pay attention to indoor ventilation. At the same time, ensure that the fire prevention passage in the workshop is unblocked. No items are allowed to be placed at the exits and walkways.

Note 4: In the clean workshop, it is not allowed to privately pull the power and wires. If it is really needed, it must be reported to the manager of the production department for approval. It should be handled by the power equipment room and removed in time after use.

Note 5: During the operation of oil-fired boilers, inspections should be strengthened, and abnormalities should be handled in time.

Note 6: Avoid all kinds of electrical equipment and lines from being wet and overloaded to prevent short circuits from causing accidents. The use of various equipment must strictly abide by the operating regulations, and illegal operations are strictly prohibited.

Note 7: The use of open flames is prohibited in clean workshops. If it is really necessary, the consent of the Security Department must be obtained, and it can only be used after effective security measures have been taken. Special persons shall be responsible during the use, and ensure that it is handled properly without hidden dangers after use.

Note 8: The clean workshop should be equipped with a gas alarm device, and a gas detector should be installed in the storage and use place. When the gas alarm sends out an alarm signal, it should immediately cut off the supply source, issue an alarm to the site staff, and open the exhaust equipment to exhaust air.

Clean room sliding doors、hpl cleanroom wall、clean room windows etc find professional manufacturer Wonzone