Overview:

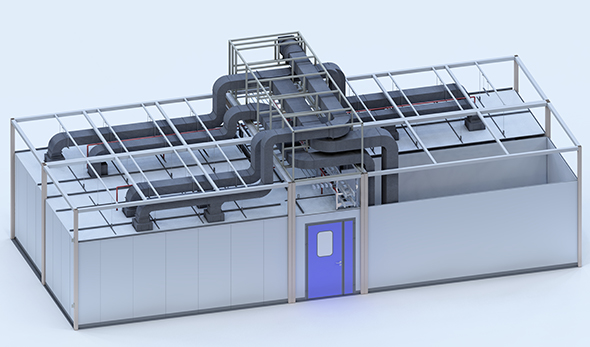

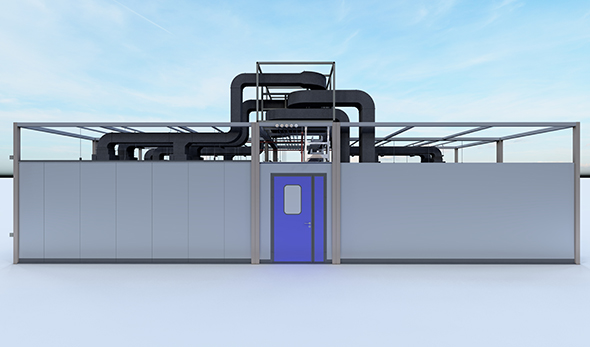

The modular laboratory/clean room is to re-plan and design each functional system that originally needs to be installed on the construction site according to a certain modulus, split it into multiple high-strength modular structures, and integrate various functions at the same time to achieve the use effect....

Product Origin:

ChinaShipping Port:

ShanghaiLead Time:

25

Detailed introduction:

1)The modular laboratory is composed of multiple fixed modules, including maintenance structure, ceiling structure, piping, electrical, and ventilation systems. The modular laboratory will be prefabricated and assembled in the factory. All piping systems and equipment, After the electrical and other system connections are completed, trial operation can be carried out, and customers can accept the goods first before taking delivery.

2)In addition to integrating modular components that meet the requirements of indoor temperature, humidity, cleanliness, and sterile environment into each module, the modular clean room can also integrate the customer's production equipment inside the modular unit, such as pharmaceutical equipment and Process pipelines, process gases and equipment power supply, etc., can be assembled and ready for production operation.

Features:

1. High strength, good stability and earthquake resistance;

2. Reusable and no loss;

3. Prefabricated and processed in the factory, and can be picked up after acceptance;

4. Production equipment and process pipelines can be integrated into the modular system at the same time;

5. The construction period is extremely short and assembly can be completed within a few days;

6. Large-area modular design can be carried out to meet different usage needs.

Refer picture:

Social Issues Solved:

Due to the general aging of the population around the world, and the poor working conditions of construction personnel, a large number of young people prefer to choose to enter offices or factories instead of going to the project site for construction, resulting in a decrease in the number of construction personnel and an increase in their age. Adopting the mode of modular building and modular clean room/laboratory, a large amount of production and processing work only needs to be completed in the factory and qualified for debugging, and then transported to the designated place for small workload assembly work as required. Great The problem of saving engineering construction labor is also achieved. At the same time, the effect of reuse can also be achieved. Even if the project is relocated, the modular clean room can be simply dismantled and transported to other locations, which not only saves costs, but also saves energy!