The air pressure of the operating room varies according to the cleanliness requirements of different areas (such as the operating room, sterile preparation room, hand brushing room, anesthesia room, and surrounding clean area, etc.). Different levels of laminar flow operating rooms have different air cleanliness standards. For example, the United States Federal Standard 1000 is the number of dust particles ≥0.5μm per cubic foot of air, ≤1000 particles or ≤35 particles per liter of air. The standard of 10,000-level laminar flow operating room is the number of dust particles ≥0.5μm per cubic foot of air, ≤10,000 particles or ≤350 particles per liter of air. And so on. The main purpose of ventilation in the operating room is to eliminate exhaust gas in each work room; to ensure the necessary amount of fresh air in each work room; to remove dust and microorganisms; to maintain the necessary positive pressure in the room.

There are the following two mechanical ventilation methods that can meet the ventilation requirements of the operating room. Combined use of mechanical air supply and mechanical exhaust: This type of ventilation can control the number of air changes, air exchange volume and indoor pressure, and the ventilation effect is better. Mechanical air supply and natural exhaust air are used together. The air exchange and the number of air exchanges in this ventilation method are limited to a certain extent, and the ventilation effect is not as good as the former. The cleanliness level of the operating room is mainly distinguished by the number of dust particles and the number of biological particles in the air. Currently, the most commonly used is the NASA classification standard. Purification technology achieves the purpose of sterility by controlling the cleanliness of the positive pressure purification air flow.

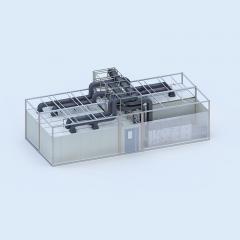

According to different air supply methods, purification technology can be divided into two types: turbulent flow system and laminar flow system.

(1) Turbulent flow system (Multi-Directional Manner): the air supply outlet and high efficiency filter of the turbulent flow system are located on the ceiling, and the return air outlet is located on both sides or the lower part of the wall. The filter and air treatment are relatively simple and the expansion is convenient. , The cost is low, but the number of air changes is small, generally 10-50 times/h, which is prone to vortex flow. Pollutant particles may suspend and circulate in the indoor vortex area to form polluted airflow and reduce indoor purification. It is only applicable to clean rooms of the 10 000 to 1000 000 class in the NASA standard.

(2) Laminal Flow System: The laminal flow system uses a uniformly distributed and appropriate flow rate airflow to bring particles and dust out of the operating room through the return air outlet, without generating eddy currents, so there is no floating dust, and the degree of purification can be changed. The air frequency increases with the increase, and it is suitable for the 100-level operating room of NASA standard. However, the damage rate of the filter seal is relatively large, and the cost is relatively high.