Why is modular clean room a revolution in the clean room industry? Let’s look at the following.

In 1913, American Henry Ford created the assembly line, which reduced the assembly time of a car from the original 12 hours to 90 minutes. At the same time, standardized production in all aspects of the assembly line also reduces the dependence of automobile quality on the level of assembly workers. The assembly line is one of the great inventions of modern society, and other industries have suit and promoted it.

In the construction industry, prefabricated modular buildings are on the rise. On April 1, 2023, Ni Hong, Minister of the Ministry of Housing and Urban-Rural Development, said that houses should be built like cars. "Vigorously develop prefabricated buildings to enable standardized design, factory production, and assembly construction of houses. This will not only facilitate the renovation and renovation of old houses, facilitate maintenance, but also help reduce environmental pollution."

On June 30, the national concrete modular high-rise building-Shenzhen Longhua Zhangkengjing project was completed and delivered. Compared with traditional construction methods, the completion and delivery period of the project was reduced from 2.5 to 3 years to 1 year, and the degree of industrial standardization increased by 80%. , solid waste emissions were reduced by 50%, and on-site labor was reduced by 50%, achieving "building a house like building a car" and becoming a national model project that combines new building industrialization and intelligent construction.

In the domestic clean room industry, there are already pioneers in modular clean rooms. Up to now, modular clean rooms have been developed for many years and are deeply loved by customers.

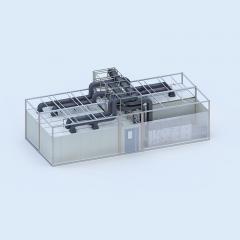

Its characteristic is that the clean room is split into various modules, standardized production in the factory, and then transported to the site for rapid construction, which reduces the dependence of traditional clean room decoration on the level of workers. The construction site has less pollution and noise, and is conducive to follow-up. relocation, expansion, upgrade and other needs.

The difference between modular clean room and traditional clean room engineering:

1. Surround maintenance: frame + painted or stainless steel plate, easy to set up, dismantle and expand.

2. Top: FFU can be combined in different combinations and has its own power. It does not require a large air-conditioning system or complex equipment such as air ducts.

3. The construction period is short. Except for sealants, wires, and some screws, 98% of the materials can be reused.

4. With high appearance, it not only meets production needs, but is also suitable for visiting.

5. More suitable for cleaning needs of small areas below 300㎡.