Purification engineering has become an indispensable industry in today's society. Purification decoration is used in many fields. So what are the requirements for doors and windows in the implementation of this project? 1. The purification and decoration project is an integral part of the enclosure structure. In addition to the requirement of airtightness, it also requires the surface to be flat and smooth, without dust accumulation, just like the wall. The glass of double windows should be flush with the inner and outer walls respectively. When metal beading is used for single-glazed windows, the metal beading should be made into an arc shape or have a certain slope to facilitate cleaning and not easy to install a window sill. 2. The sealing materials for clean room doors and windows include rubber strips, silicone rubber, sealants, and single and double-sided pressure-sensitive adhesive strips, etc. 3. The gaps between doors and windows are roughly divided into fixed gaps and movable gaps. Fixed gaps, such as those of fixed windows, are easier to handle, and you can use "one-and-for-all" sealing materials; movable gaps, such as the gap between door leaf and door frame, cannot be treated like fixed gaps. It depends on the material, quality, opening frequency, and With thresholds, whether it is directly connected to the outside air, etc., comprehensively consider the door leaf, door frame, hardware material, sealing strip and its action mode, and make corresponding design in advance. Professional clean room manufacturer, mainly dedicated to the production and research and development of clean room engineering, equipment, materials, etc.

The clean room ceiling system is designed according to the characteristics of the clean room. It has simple processing, convenient assembly and disassembly, and is convenient for daily maintenance after the clean room is built. The ceiling system is modular in design and has large plasticity, which can be factory-produced or cut on site. The pollution of processing and construction is greatly reduced. The system has high strength and can walk on it. It is especially suitable for high-clean areas, such as electronics, semiconductors, and medicine. industry. Ceiling system composition: 1.T-bar: 1) T-shaped structure, dry ceiling, anode aluminum material, surface electrophoresis treatment. 2) Sprinklers, smoke detectors and lighting wires can be installed at the T-bar cross joint 3) Clean room teardrop lighting can be installed under the T-bar 2. Connector: 1) The connecting parts include cross joints, T-shaped joints, corner joints, and zinc alloy materials. The entire system is screwed together to form a whole. 2) Galvanized full wire suspension rod, with adjuster to adjust the height of the ceiling, connected by clamps and nuts. 3) All screws and nuts are galvanized 3. System scalability: high efficiency filters, FFU, etc. can be easily installed. To Clean room FFU ceiling connection node 1. Check the baseline—check the datum level—prefabrication of boom—stake out boom installation—installation of boom—prefabrication of ceiling keel—installation of ceiling keel—level adjustment of ceiling keel—position of ceiling keel—installation of cross reinforcement piece—measurement of abnormal keel Dimensions—Interface closing—Ceiling keel gland installation—Ceiling keel level adjustment 2. check the baseline A. Be familiar with the drawings carefully, and confirm the construction area and the position of the cross reference line according to the relevant data. B. Check the ceiling reference line with theodolite and laser level. 3. Check the reference elevation Determine the elevation of the ceiling according to the ground or raised floor 4. Boom prefabrication A. According to the floor height, calculate the length of the boom required for each ceiling height, and then cut it. B. After processing, the boom that meets the requirements is pre-assembled with the square regulator and other accessories. 5.Installation of boom: After setting out the boom, install the boom in a large area according to the position of the boom, and fix it on the airtight ceiling keel through the flange anti-slip nut. 6.prefabricated ceiling system When the keel is prefabricated, the protective film cannot be removed, the hexagon socket screws need to be tightened, and the pre-assembly area is moderate. 7.Ceiling keel installation The prefabricated ceiling keel is hoisted onto the T-shaped screw pre-assembled by the boom, the square adjuster is offset from the center of the cross joint by 150mm, and the T-shaped screw and flange anti-slip nut are...

The slot-sealed flat-closed clean room door of the door and fan of the open clean room is the most commonly used type of clean room door in the clean workshop. It is usually used for traffic or transportation, and is very convenient for emergency evacuation in case of fire, which is very convenient. The elastic material of the forming section is usually chosen as the sealing strip to fix and seal at the state of the seam. The opening width of common sliding doors clean room is less than 1800 mm in double inner clean room doors and 2100 mm in double outer clean room doors, and the height of the opening is in the range of less than 2400 mm. The setting of the sealing strip. In the case of frequent opening and closing of the doors and fans of clean rooms, it excepts the following situations:some outside clean rooms door and windows, which may install the sealing strips on the doors and fans of clean rooms to avoid the transportation of the heavy equipment , or some doors of inner clean rooms are not allowed to set the doors of clean rooms on the ground because of workshop transportation, and only suspended sweeping can be installed at the bottom of the doors and fans of clean rooms close to the ground. In general, in order to avoid the hand model, foot step or car collision as far as possible, and less affected by the operation and transportation, the small section forming sealing strips of several millimeters in length and width is laid on the concealed groove part of the door lift of the clean room, and then tightened by the closure of the door fan of the clean room. The sealing strip should be laid continuously along the periphery of the movable gap in order to form a trapped and closed ring sealing line after the door of the clean room closes. When the sealing strip is set at the door building and the door fan of the clean room respectively, it is necessary to pay attention to the good connection of the pottery and minimize the small gap between the airtight strip and the crack of the clean room doors and windows. Welcome to choose and buy the clean room equipment produced by Wonzone clean room doors and windows factory.

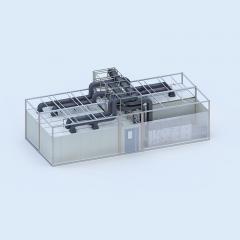

Many clients ask the same question at the very beginning of a project: “Do we really need a cleanroom?” In life sciences and high-precision manufacturing, the answer is almost always yes. A well-designed cleanroom projects solution is not just a physical space—it is a long-term, integrated engineering system. As a professional cleanroom solution provider, Wonclean explains how cleanroom projects work, from concept to sustainable operation. What is a Cleanroom—and Why Do Projects Depend on It? By definition, a cleanroom is a controlled environment that uses engineering methods to continuously limit airborne particles, microorganisms, and chemical contaminants. In real projects, however, “clean” is not a fixed condition. It is an ongoing process that must be designed, monitored, and maintained over time. The Core Value of Cleanroom Projects Cleanroom projects deliver value in four critical ways: Product protection: Preventing particles or microbes from damaging chips, pharmaceuticals, or precision components Process protection: Ensuring consistent manufacturing results and reliable experimental data Personnel & environmental safety: Creating containment barriers for hazardous chemicals or biological agents Regulatory compliance: Meeting mandatory requirements such as GMP, ISO standards, and USP regulations In regulated industries, a cleanroom is not an enhancement—it is a prerequisite. How Are Cleanroom Projects Planned? Successful cleanroom projects usually begin with three fundamental decisions. Cleanliness Levels and Applicable Standards Different industries require different cleanliness classifications: Application Common Standards Pharmaceutical & biotech GMP A/B/C/D, ISO 5–8 Sterile compounding USP 797 / USP 800 Medical devices ISO 13485 High-tech manufacturing ISO 5–7 Higher cleanliness levels allow fewer particles and demand greater system stability. Airflow and System Integration The “core systems” of a cleanroom include: HVAC systems (HEPA/ULPA filtration, air change rates, airflow patterns) Pressure control to maintain clean-to-less-clean airflow Construction materials that are smooth, sealed, and easy to clean Integrated utilities such as power, gases, and data This is where modern cleanroom technology becomes essential—determining whether the room can operate reliably long after validation. Personnel and Material Flow Management In most cleanroom projects, people are the largest contamination source. Effective designs therefore include: Structured gowning procedures (primary and secondary gowning) Separate personnel and material airlocks (PAL/MAL) Clear zoning of critical, support, and buffer areas How New Technologies Are Transforming Cleanroom Projects Today’s cleanrooms are far more than steel panels and air handlers. Emerging Trends in Cleanroom Design IoT-based monitoring for particles, pressure, temperature, and humidity Predictive maintenance to reduce downtime and filter failures Digital compliance systems for audit tra...

1. Cleaning of the clean room should be done before the end of the day and after the end of the process operation. 2. Cleaning should be carried out in the operation of clean room air conditioning system. 3. After cleaning, the air-conditioning system will continue to operate until the required cleanliness level is restored, generally not less than the self-cleaning time of the clean room. 4. Sweeping mops and rags should not be made of easy-to-remove fabrics. They can generally be made of long-fibre materials or polyurethane sponges. 5. In order to prevent cross-contamination, clean rooms with different cleanliness levels should have their own special cleaning supplies, and garbage should be put into dustproof bags (plastic bags) and taken out. 6. Clean room cleaning detergent can be prepared by adding 30 g neutral residual liquid detergent per liter of water. 7. Purified water should be used instead of tap water for cleaning high-level clean rooms. Disinfectants used should be replaced regularly to prevent microorganisms from developing resistance to antibiotics. 8. When large objects are moved into a clean room, they should be cleaned initially by vacuum cleaner in general environment, and then further treated by vacuum cleaner or wiping method in quasi-clean room. During the period when the clean room purification system stops operating, large objects are not allowed to be moved into the clean room. 9. Small items that need to be brought into the clean room should be wiped and cleaned in the quasi-clean room first, and then brought in through the transfer window or into the handling box. 10. Fire fighting equipment, safety doors and safety passages in the clean room should be clearly marked, and staff members should be familiar with their locations. Safety doors must be open at any time, and no debris should be piled up in safety passages. Safety fire protection facilities should be checked regularly. 11. When a fire alarm occurs in a clean room, an alarm should be issued immediately, the fan and all equipment in the clean room should be closed, and the power supply and flammable gas access should be cut off. (System and fire alarm equipped with fire valve or fire switch will automatically shut down the fan and need manual reset afterwards. Welcome inquiry clean room partition systems、cleanroom wall panels 、clean room false ceiling、clean room doors&windows etc.

Clean room parameters are a more complicated issue. With the advancement of technology, more and more industries apply clean rooms. Clean rooms in different industries have different parameters, so there are more and more technical parameters. The microelectronics industry has higher requirements for the concentration of air-floating particles; the pharmaceutical industry has higher requirements for the concentration of air-floating bacteria; the precision measurement and precision processing industries have higher requirements for temperature and vibration. In view of the above situation, the technical parameters of the clean room can be divided into two categories: basic parameters and special parameters. Second, the basic parameters of the clean room 1. Cleanliness Cleanliness is the most important and basic technical indicator of a clean room, and its unit is: the number of particles with a particle size not less than a certain scale per unit volume of air. The microelectronics industry has the highest requirements for cleanliness, followed by the optoelectronics industry. 2. Microbial concentration Microbial concentration is another important technical indicator of a clean room. Its unit is: the number of microorganisms per unit volume of air. The bioengineering industry has the highest requirements for microbial concentration, followed by the medical, pharmaceutical, food, beverage, and cosmetic industries. There are many types of microorganisms, including viruses, bacteria, fungi, algae, spores, pollen, and mites. Microorganisms in the air are part of the airborne particles, to be precise the more harmful part. Usually the concentration of bacteria in the air is measured. 3 .temperature Temperature is the basic working condition. Almost all clean rooms have clear requirements for temperature. Temperature will affect the scale of the object, thereby affecting the accuracy of processing, so precision processing has quite strict requirements on temperature. Temperature will affect the parameters of the instrument, resulting in measurement errors, so precision measuring instruments have higher requirements for temperature. 4. Humidity Humidity is also a basic working condition. Almost all clean rooms have clear requirements for humidity. Excessive humidity will cause chemical reactions of many substances, which will affect the quality of products, and even cause equipment failure and product scrap. If the humidity is too low, many substances will be dehydrated and deformed and lose their original functions. 5. Wind speed and volume Adequate wind speed and air volume are the guarantee of cleanliness. Excessive wind speed and air volume not only waste energy, but sometimes affect normal work. 6. Air pressure and pressure difference Normal air pressure is the basic condition for normal work. The necessary pressure differe...