With the continuous development of pharmaceutical technology, the use of clean rooms is becoming more and more widespread, and its role is becoming more and more important. How to maintain cleanliness in clean rooms and how to reasonably control pollution sources are issues that pharmaceutical companies care about and attach great importance to. This article introduces how to keep a clean room clean from several aspects: cleaning requirements and precautions, maintenance and management of clean room equipment, clean room staff management, management of materials entering and exiting the clean room, and operation and maintenance of the air conditioning system. Cleaning requirements and precautions 1. When cleaning the clean room walls, special clean room dust-free cloth and special cleaning agent should be used; 2. Prepare a cleaning agent with 90% deionized water and 10% isopropyl alcohol; 3. Check the trash can every day and clean it in time; 4. The floor must be vacuumed regularly, and the completion of the work should be marked on the chart every time a shift is handed over; 5. Use a special mop to clean the clean room floor, and wax the floor in strict accordance with the plan and cleaning procedures, and anti-static wax must be used; 6. A special vacuum cleaner with a high-efficiency filter should be used for vacuuming in the clean room; 7. All clean room steel purification doors need to be inspected and wiped dry; 8. Vacuum and wipe regularly under the raised floor and in the air return wall; 9. When working, you must remember to always wipe from top to bottom, and wipe from the farthest point to the direction of the door. 10. After the cleaning work is completed, all cleaning supplies must be stored in the designated cleaning room and stored separately from ordinary tools to avoid cross-contamination and placed neatly. Maintenance and management of clean room equipment 1. Material selection: In order to keep the interior of the clean room clean for a long time, material selection is very important. Materials should be selected that are smooth and do not produce their own pollution. They are also durable, corrosion-resistant, sterilization-resistant, and easy to clean. Otherwise, microorganisms will breed. place. 2. Cleaning work: Clean and wipe the equipment before moving it into the clean room. Before cleaning, you must understand the clean room equipment, know the correct disassembly method, cleaning sequence, and cleaning precautions, which can make the cleaning work more in line with specifications. At the same time, Avoid damaging equipment during cleaning. 3. Regular cleaning: Carry out regular cleaning and disinfection according to the requirements of clean rooms of different levels, and keep records. Cleaning of sterile equipment, especially parts and components that are in direct contact with drugs, must be sterilized, and the date of sterilization must be marked, and microbiological verification must be carried out if necessary. ...

HPL (High-Pressure Laminate) doors and steel doors are two different types of doors with distinct characteristics. Here are some key differences between the two: Material: HPL doors, also known as laminate doors, are made from layers of resin-impregnated kraft paper that are bonded together under high pressure and temperature. The outer layer is a decorative laminate, which gives the door its aesthetic appearance. On the other hand, steel doors are made of steel sheets, typically with an insulated core, providing structural strength and durability. Appearance: HPL doors offer a wide range of design options and aesthetics. The decorative laminate surface can be customized with various colors, patterns, and textures, mimicking the look of wood, stone, or other materials. Steel doors, on the other hand, have a more industrial or utilitarian appearance, although they can be painted or coated to achieve different finishes. Durability: Both HPL doors and clean room steel doors are durable, but steel doors are generally considered to be stronger and more resistant to physical impact, such as dents and scratches. Steel doors also have better resistance to fire, moisture, and extreme weather conditions, making them suitable for exterior applications where security and durability are prioritized. HPL doors are more susceptible to damage from heavy impact or exposure to moisture over a long period. Maintenance: HPL doors are relatively low maintenance and easy to clean. The laminate surface is resistant to stains, chemicals, and fading, requiring only regular wiping with mild soap and water. Steel doors, while durable, may require occasional maintenance to prevent rust and corrosion. They may need repainting or touch-ups over time to maintain their appearance and protection. Sound and Thermal Insulation: HPL doors provide some level of sound and thermal insulation due to their construction, but they are not as effective as steel doors in this regard. Steel doors, especially those with insulated cores, offer better insulation properties, reducing noise transmission and heat transfer between different spaces. Security: Steel doors are generally considered to be more secure than HPL doors. The steel construction and robustness of steel doors make them harder to break or force open, providing enhanced security for residential, commercial, or industrial applications. It's important to consider the specific requirements of your project, such as aesthetics, durability, security, and maintenance, to determine which type of door, HPL or steel, is most suitable for your needs. What material is HPL? HPL is a manufactured composite material. It consists of printed decoration paper fused to multiple sheets (6-8 pieces) of Kraft paper saturated with a synthetic thermosetting resin.

The FFU (Fan Filter Unit) ceiling system is a specialized type of ceiling system commonly used in cleanrooms and controlled environments where strict air quality and cleanliness are required. It consists of several Fan Filter Units mounted in a grid pattern on the ceiling, along with a plenum or ducting system for distribution of conditioned air. Here is a detailed introduction to the FFU ceiling system: Fan Filter Units (FFUs): FFUs are the primary components of the FFU ceiling system. Each FFU consists of a fan, a high-efficiency particulate air (HEPA) or ultra-low particulate air (ULPA) filter, and a housing. The fan draws air from the room, passes it through the filter, and then delivers it back into the controlled environment. The filter captures airborne particles and helps maintain a clean and sterile environment. FFUs are typically lightweight, easy to install, and can be operated individually or in synchronization with the overall environmental control system. Ceiling Grid: The FFUs are mounted in a grid pattern on the ceiling of the cleanroom or controlled environment. The ceiling grid provides structural support for the FFUs and ensures proper distribution of conditioned air throughout the space. The grid is usually made of aluminum or steel and is designed to be sturdy and easy to clean. Plenum or Ducting System: The FFUs are connected to a plenum or ducting system that distributes the conditioned air evenly across the room. The plenum is an enclosed space above the ceiling where the air circulation system is located. It allows for uniform airflow distribution, avoiding turbulence and creating a continuous positive pressure within the cleanroom. Control System: The FFU ceiling system is typically integrated with a central control system that regulates the operation of the FFUs. The control system monitors and adjusts parameters such as airflow velocity, pressure differentials, and filter condition. It ensures that the cleanroom operates within specified cleanliness levels and maintains a controlled environment. Advantages of FFU Ceiling System: The FFU ceiling system offers several benefits in cleanroom applications. These include: High Air Filtration Efficiency: The HEPA or ULPA filters in the FFUs remove airborne particles, including dust, microorganisms, and contaminants, ensuring clean and sterile air. Modular and Scalable Design: The modular nature of FFUs and the ceiling grid allows for easy customization and expansion of the system, making it suitable for different cleanroom sizes and configurations. Energy Efficiency: FFUs are designed with energy-efficient fans and motors, reducing power consumption and operating costs. Flexible Airflow Control: The FFU ceiling system offers precise control over airflow patterns, velocities, and pressure differentials, ensuring uniform distribution of clean air. Easy Maintenance: FFUs are designed for easy maintenance and filter replacement. They often feature filter change indicators to moni...

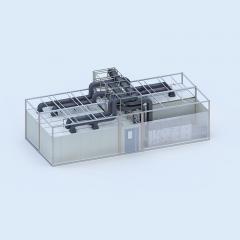

Modular laboratories play a crucial role in the pharmaceutical industry by providing flexible and efficient spaces for various research and manufacturing processes. Here are some key applications of modular laboratories in the pharmaceutical field: Research and Development: Modular laboratories offer a versatile environment for pharmaceutical research and development activities. They can be quickly reconfigured to accommodate different experiments and research requirements. Modular lab spaces allow scientists to conduct drug discovery, formulation development, process optimization, and analytical testing. Quality Control and Quality Assurance: Modular laboratories are used for quality control and quality assurance processes in the pharmaceutical industry. These labs are equipped with instruments for performing various tests and analyses to ensure that the products meet the required standards and specifications. Testing for purity, potency, stability, and safety of pharmaceutical products can be conducted in modular lab spaces. Cleanroom Facilities: Cleanrooms are essential in pharmaceutical manufacturing to maintain a controlled environment free from particulate contamination. Modular cleanrooms provide a controlled and sterile environment for aseptic processing, sterile compounding, and other critical manufacturing processes. These cleanrooms are designed to meet specific cleanliness requirements according to industry standards, such as ISO 14644. Pilot Plant and Manufacturing: Modular laboratories can be used as pilot plants for small-scale production and process development. They provide a flexible and adaptable space for testing new manufacturing processes and equipment before scaling up to full-scale production. Modular lab spaces can be customized to meet the specific requirements of pharmaceutical manufacturing, including containment facilities for handling potent substances. Collaboration and Expansion: Modular laboratories support collaboration among different teams and departments. They can be easily expanded or reconfigured to accommodate additional equipment, personnel, or research projects. Pharmaceutical companies often use modular labs to meet fluctuating demand or for temporary research projects. Compliance with Regulations: Pharmaceutical production and research are subject to strict regulatory requirements. Modular laboratories can be designed and constructed to meet these regulations and standards, including Good Manufacturing Practices (GMP), Good Laboratory Practices (GLP), and various regulatory guidelines. Overall, modular laboratories provide a flexible and adaptable environment for various pharmaceutical activities, enabling efficient research, development, manufacturing, and quality control processes in the industry. New product launch:Prefabricated laboratory、Modular clean room、Fold laboratory、Container laboratory.

HPL (High-Pressure Laminate) panel has an important role in the clean room industry Clean room is a special environment with strict requirements for air quality, temperature, humidity and cleanliness, often used in medical, pharmaceutical, semiconductor and other industries.The following is the role of HPL sheet in several aspects of the clean room industry: Surface corrosion resistance and easy cleaning: HPL panels are resistant to corrosion and resist the erosion of chemicals and cleaners commonly found in clean rooms.Its surface is smooth, does not absorb dust and dirt, and is easy to clean.This is essential to maintain the cleanliness of the clean room. Antibacterial properties: The clean room is required to prevent the growth and spread of bacteria, mold and other microorganisms.HPL wall panel usually have antibacterial properties that inhibit the growth of bacteria and help maintain a hygienic environment in the clean room. Wear resistance and durability: HPL panels have excellent wear resistance and durability and can withstand long-term use and frequent cleaning in clean room environments.They are not susceptible to wear, deformation or mechanical impact, and can maintain a long service life. Flame retardant: HPL panels usually have good flame retardant properties and can resist the spread and combustion of flames, providing higher safety. Good appearance and design options: HPL panels are available in a variety of colors, textures and decorative surface options to meet the requirements of clean room design.They have a good appearance and decorative effect, which can create a beautiful and comfortable working environment for the clean room. In general, HPL sheet in the clean room industry has the advantages of corrosion resistance, easy to clean, antibacterial, wear-resistant, durable, flame retardant, etc., can provide surface materials that meet the requirements of clean rooms, and help to maintain the cleanliness, hygiene and safety of clean rooms.

The cleanroom ceiling system plays a critical role in maintaining cleanliness, controlling airflow, and integrating various utilities within a cleanroom environment. The structure of a cleanroom ceiling system typically consists of several key components, which I'll outline below: Ceiling Grid: The ceiling grid forms the primary structural support for the cleanroom ceiling system. It is usually made of aluminum or steel and comprises a network of interconnected beams and crossbars. The grid provides stability and allows for the integration of other ceiling components. Ceiling Panels: Cleanroom ceiling panels, also known as ceiling tiles or plenums, are suspended from the ceiling grid and form the visible surface of the cleanroom ceiling. These panels are designed to have smooth, cleanable surfaces to minimize particle generation. They are often made of materials such as aluminum, steel, or fiberglass-reinforced plastic (FRP). Gasketed Seals and Joints: To ensure an airtight and particle-free cleanroom environment, gasketed seals and joints are used in cleanroom ceiling systems. These seals help minimize air leaks and prevent contamination from entering the cleanroom through gaps or openings. Lighting Fixtures: Cleanroom ceiling systems incorporate lighting fixtures that meet the specific lighting requirements of the cleanroom environment. These fixtures are typically recessed into the ceiling panels to maintain a smooth and clean surface. Cleanroom lighting options can include LED lights, which provide energy efficiency and generate minimal heat. Filters and HEPA/ULPA Units: Cleanroom ceiling systems often incorporate filters and High-Efficiency Particulate Air (HEPA)/Ultra-Low Penetration Air (ULPA) units to provide clean, filtered air to the controlled environment. These units are integrated into the cleanroom ceiling, ensuring that the supplied air is free from particles and contaminants. Utilities Integration: Cleanroom ceiling systems may include utility services integration, such as ductwork for HVAC (Heating, Ventilation, and Air Conditioning) systems, piping for clean gases, or electrical conduits for power distribution. These utilities are often concealed within the ceiling system to optimize space and maintain a clean appearance. Access Points and Hatches: Cleanroom ceiling systems may have access points and hatches for maintenance and equipment installation purposes. These access points allow for easy entry into the plenum space above the cleanroom ceiling, enabling maintenance personnel to access utilities or perform equipment adjustments without compromising cleanliness. It's important to note that cleanroom ceiling systems can vary depending on the specific requirements of the cleanroom, such as cleanliness class, airflow patterns, and ceiling height. Cleanroom design professionals and cleanroom construction companies utilize industry standards and guidelines to ensure the ceiling system is designed and installed correctly to mainta...