Shanghai, China, June 24, 2025 - - Wonclean, a leading provider of clean room solutions, successfully demonstrated its cutting - edge products and technologies at CPHI&PMEC China 2025, held from June 24 to 26 at the SNIEC in Shanghai. The event proved to be highly rewarding for Wonclean as it garnered significant attention, trust, and support from both new and existing customers, solidifying its position in the industry.

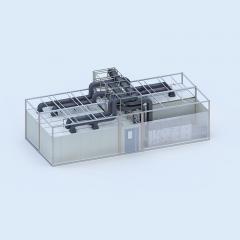

At “BOOTH NO.N4B26”, Wonclean presented an impressive array of products, including its advanced “Modular Cleanroom”, which attracted numerous visitors with its flexible design and efficient performance. The company's “Clean Room Wall System” also drew considerable interest, showcasing its durability and ease of maintenance. Additionally, Wonclean's “Clean Room Door&Window”, “Clean Room Equipment”, and “Laboratory Furniture” were displayed to highlight the company's comprehensive capabilities in providing high - quality clean room solutions.

Many loyal customers took the opportunity to visit Wonclean's booth during the exhibition. These returning clients not only showed their continued trust in Wonclean's products but also engaged in in - depth discussions about potential collaborations and custom - made solutions for their specific needs. Their presence and positive feedback served as a powerful endorsement of Wonclean's commitment to excellence and customer satisfaction.

The exhibition provided Wonclean with valuable insights into market trends and customer requirements. By interacting with a diverse group of industry professionals, the company was able to gather important information that will guide its future research and development efforts. Wonclean's participation in CPHI&PMEC China 2025 has been a resounding success, further enhancing its brand reputation and expanding its customer base.

Wonclean would like to express its gratitude to everyone who visited the booth and showed interest in its products. The company looks forward to applying the knowledge gained from the exhibition to continue delivering innovative and reliable clean room solutions to its global clientele. For more information about Wonclean and its full range of products, please visit the company's website or contact their customer service team.

Wonclean is a premier manufacturer of clean room solutions, specializing in the design and production of “Modular Cleanroom”, “Clean Room Wall System”, “Clean Room Door&Window”, “Clean Room Equipment”, and “Laboratory Furniture”. With a strong emphasis on quality and innovation, Wonclean strives to meet the highest standards of cleanliness and functionality required by various industries.

For media inquiries, please contact:

Add: No.68 LuXiang Road, Kunshan, China

Email: Allen@wonclean.com

Web: www.wonclean.com

Tel: 0512-5780 2738