clean room roll up doors are essential components for maintaining operational stability and contamination control in cleanroom environments. As a professional cleanroom engineering company, Wonclean continuously optimizes door structure, airflow control capability, and operational efficiency to support high-standard clean environments. Through rigorous engineering methods and advanced design concepts, cleanroom doors can maintain sealing performance and durability under high-frequency usage, providing stable and reliable environmental protection for various precision manufacturing industries. Application Value of clean room roll up doors for Enhanced Environmental Isolation clean room roll up doors are known for their high sealing performance, rapid opening and closing, and ability to reduce air exchange, effectively minimizing contaminants entering sensitive areas. Their structural design integrates the core principles of clean room door design, optimizing materials, sealing components, and drive systems. This ensures stable performance in high-frequency operation environments, meeting strict cleanliness requirements in electronics manufacturing and biopharmaceutical industries. Manufacturing Quality that Improves clean room roll up doors Operational Efficiency clean room roll up doors require strict control over structural strength, durability, and sealing stability during manufacturing to ensure reliability during long-term operation. As a professional clean room doors manufacturers, Wonclean applies rigorous process management and quality testing to ensure the roll-up doors operate smoothly and precisely even under high workloads in cleanrooms, delivering higher operational efficiency and environmental safety for complex workflows. In cleanroom construction and long-term operation, the performance of clean room roll up doors directly affects environmental cleanliness, operational efficiency, and system stability. Wonclean will continue to uphold strict standards, advanced manufacturing processes, and ongoing engineering optimization to provide high-quality roll-up door solutions. By consistently enhancing door structure and functional performance, we strive to deliver safer, more efficient, and more reliable cleanroom environments for our clients.

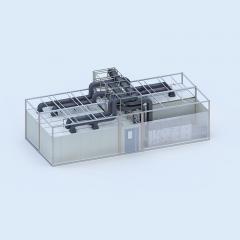

With the continuous advancement of technology industries and their increasing demands for clean environments, traditional construction models can no longer meet the needs for rapid deployment and flexible adjustments. As a leading provider of cleanroom solutions, Wonclean introduces innovative portable clean room, prefabricated laboratory, and prefabricated laboratory units, offering smarter and more efficient clean environment solutions for various industries. Flexibly Deployable Mobile Cleanrooms portable clean room is reshaping the usage patterns of clean spaces with its exceptional mobility and flexibility. These mobile cleanrooms adopt a modular design and are equipped with complete air filtration systems and environmental control systems, enabling installation and operation within a few days. Whether for R&D projects, emergency medical needs, or production line expansion, mobile cleanrooms can provide ISO-standard clean environments while supporting repeated disassembly and relocation, significantly improving usage efficiency and return on investment. Prefabricated Laboratories: Integrated and Modular Solutions prefabricated laboratory represents a major innovation in laboratory construction models. All components are standardized and pre-tested in the factory, greatly reducing on-site construction time. Prefabricated laboratories integrate professional ventilation, water supply, drainage, and electrical systems, and can be customized according to experimental requirements. This construction method not only ensures precise control of environmental parameters but also significantly enhances engineering quality and construction safety. prefabricated laboratory units, as an advanced solution for prefabricated laboratories, take modular concepts to the extreme. Each standard unit is an independent module with complete functionality, supporting free combination and flexible expansion. From simple testing rooms to complex research centers, these prefabricated units can be quickly assembled while ensuring independent and precise control of environmental parameters in each area. This construction method is particularly suitable for scientific research projects requiring phased implementation or future expansion plans, providing users with maximum configuration flexibility. As industry demands continue to evolve, the advantages of portable clean room for rapid deployment, prefabricated laboratory for efficient construction, and prefabricated laboratory units for intelligent expansion will become even more prominent. Leveraging its professional technical team and extensive project experience, Wonclean can provide the most suitable modular clean space solutions for customers, helping enterprises rapidly establish safe, compliant, and efficient clean environments.

In the planning and construction of modern chemical laboratories, the selection of furniture directly impacts experimental efficiency and operational safety. Suitable laboratory furniture must not only withstand the corrosion from chemical reagents but also provide researchers with a safe and efficient working platform. Addressing this core requirement, Wonclean specially introduces professional solutions for chemistry lab furniture and laboratory table with sink, offering comprehensive support for various types of laboratories. The Cornerstone of Safe and Durable Lab Operations Professional chemistry lab furniture forms the foundation for safe laboratory operations. This type of furniture is manufactured using materials with excellent corrosion resistance, such as epoxy resin countertops and stainless steel structures, enabling them to resist erosion from various acidic and alkaline chemical reagents. Wonclean's laboratory furniture series emphasizes ergonomic design, ensuring tidy and organized experimental operation areas through reasonable functional zoning and robust structural design. Simultaneously, it meets ergonomic requirements, effectively enhancing researchers' comfort and work efficiency. Workstation with Integrated Water Supply and Drainage Systems The laboratory table with sink, integrated with water supply and drainage systems, brings significant convenience to experimental operations. This type of laboratory bench is not only equipped with corrosion-resistant sink components but also ensures smooth water supply and drainage through scientific pipeline layout. The laboratory sink tables provided by Wonclean adopt an integrated design, with seamless connections between the countertop and the sink, preventing liquid leakage and bacterial growth. Additionally, they provide ample operating space and storage areas, perfectly meeting the needs of chemical experiments and cleaning processes that require frequent water use. In summary, whether it is the basic configuration of chemistry lab furniture or the specialized laboratory table with sink, both are indispensable components in building a modern laboratory. Leveraging its in-depth understanding of laboratory requirements and extensive project implementation experience, Wonclean can provide customers with comprehensive services ranging from product selection to spatial planning, helping to create a safe, efficient, and compliant laboratory working environment.

In the field of cleanroom construction, the choice of materials directly impacts the cleanliness classification and operational efficiency of the entire environment. Wonclean is committed to providing customers with the most advanced wall and ceiling solutions. Among these, hpl sandwich panel and pur panel, as two core materials, have become ideal choices for various application scenarios due to their unique performance advantages. Exceptional Surface Durability and Structural Integrity The High-Pressure Laminate (HPL) sandwich panel stands out for its exceptional durability and ease of cleaning. Its surface, made of high-pressure laminate, offers high hardness, wear and scratch resistance, and can withstand the erosion of various chemical reagents, making it highly suitable for clean areas that require frequent cleaning and strict hygiene standards. The honeycomb or rock wool core structure inside the panel ensures flatness while providing good mechanical strength, sound insulation, and thermal insulation performance, creating a durable and stable operating environment for the cleanroom. Outstanding Thermal Insulation with Safety and Energy Efficiency The Polyurethane (PUR/PIR) sandwich panel is renowned for its outstanding thermal insulation performance. Thanks to the continuous closed-cell structure of the PUR core, this panel has an extremely low thermal conductivity coefficient, effectively reducing the energy consumption of the cleanroom. Additionally, the PUR panel offers excellent sealing and moisture resistance. It is lightweight, easy to install, and demonstrates good flame retardancy in fire scenarios, providing an enclosure solution that combines safety and energy efficiency for high-standard cleanrooms. In summary, whether it is the hpl sandwich panel pursued for ultimate durability and chemical resistance, or the pur panel focused on high-efficiency thermal insulation and energy saving, both play an indispensable role in modern cleanroom construction. Leveraging its professional technical team and extensive project experience, Wonclean can provide the most appropriate panel selection and customized solutions based on your specific needs, helping you build a safe, efficient, and compliant clean space.

Clean room design often faces a core challenge: maintaining strict segregation between different zones while accommodating access needs for equipment movement and process adjustments. Traditional fixed partition walls often struggle to balance these conflicting requirements, making flexible and innovative partition solutions crucial in modern clean room planning. The easily removable area on a clean room partition wall and full glass partition wall represent ideal solutions for achieving this dynamic balance. Temporary Access Portal, Flexible Passage The easily removable area on a clean room partition wall provides the ultimate solution for large equipment or material passage requirements. This flexible opening module maintains complete sealing and flush integration with the surrounding partition during normal operations, ensuring airtight integrity and cleanliness standards. When equipment replacement, process upgrades, or bulk material transfer becomes necessary, it can be quickly and safely removed to create a temporary access point, significantly reducing construction downtime and contamination risks associated with modifying fixed walls. Wonclean's removable area solutions incorporate precision locking and sealing mechanisms that ensure performance identical to the original wall when closed, providing solid assurance for production continuity and future flexibility. Transparent Visibility, Unobstructed Monitoring In comparison, the full glass partition wall for clean rooms maximizes visual access while maintaining physical segregation. Utilizing high-strength tempered or laminated glass, it creates transparent and bright spatial boundaries that not only enhance natural lighting and reduce oppressive feelings but also enable managers to monitor production status at a glance, facilitating real-time supervision and team collaboration. More importantly, its exceptionally smooth surface is non-particulating, corrosion-resistant, and easy to clean and disinfect, fully complying with stringent clean room standards. Wonclean's full glass partition wall systems ensure structural safety and airtightness classification while creating a modern, highly transparent excellent working environment for clean rooms. In summary, an efficient modern clean room environment requires forward-thinking spatial division design. Both the easily removable area on clean room partition walls designed for dynamic adaptation and the full glass clean room partition walls employed to enhance visual communication and monitoring represent advanced design concepts that transcend traditional fixed thinking. As your professional clean room partner, Wonclean provides comprehensive services from design consultation to product integration, helping you build a future-ready clean space that is both strictly controlled and highly adaptable.

In daily cleanroom operations, preventing cross-contamination and maintaining stable environmental parameters are core challenges. A minor oversight can lead to particle ingress or pressure differential imbalance, potentially compromising an entire production batch. To address these issues, it is crucial to focus on key components that control personnel flow and the integrity of physical barriers. Manage Airflow, Eliminate Cross-Contamination The cleanroom door interlock system serves as the primary defense for ensuring airtight isolation between zones. This electromechanical system guarantees that only one door can be opened at a time, effectively preventing cross-contamination caused by air convection. The interlock systems provided by wonclean offer high reliability and can integrate seamlessly with your cleanroom management system, providing real-time access records and traceable data support for stringent production protocols. Protective Viewing Panels for Safety and Cleanliness Glass film for windows provides a critical protective solution for a often-overlooked vulnerability: the observation window. Scratches, abrasion, or the risk of glass breakage in these panels pose significant contamination and safety risks. The application of this dedicated film is an efficient and cost-effective countermeasure. It significantly enhances the glass's impact resistance, preventing shattering, while its anti-scratch surface facilitates easy and thorough cleaning and disinfection. This ensures the long-term maintenance of cleanliness and clarity. In summary, a truly reliable clean environment depends on precise control over every detail. From the access control enforced by the cleanroom door interlock system to the reinforced safety provided by protective glass film for windows, these solutions collectively build an invisible line of defense. As your trusted cleanroom partner, wonclean is committed to providing such critical components and integrated solutions, helping you safeguard the integrity of your clean environment in a smarter and more assured manner.